HA 300 is a compact equipment for simple experiments and tests. We improved an efficiency of the process by a cooling system for rapid cooling. It is used for removing air bubbles or voids in the semiconductor process using Epoxy resin such as Over Mold and Underfill. This equipment performs isotropic compression with constant temperature. It is basically made from stainless steel for chemical resistance and applied clamp type cover for automatic opening / closing. HA 300 ensure a safety and air tightness for user by multi-line pressing method. |

|

|

| |

Dimension Dimension |

| Working

Vessel Dia |

Ф 300 ㎜ x 300 ㎜ |

| Working Temperature |

~ 150 ℃ |

| Working

Pressure |

~ 20 ㎏/㎠ |

| Temp.

& Pressure Deviation |

±1.5 (%) |

| Motor Rotational Speed |

~1,750 rpm |

| Dimension |

820 (W) X 1,325 (D) X 1,500(H) |

|

| |

Features of HA 300 Features of HA 300 |

| Safety |

• Design and manufacture according to ASME pressure vessel standard

• Design and manufacture according to KGS & KOSHA

• Ensure safety by safety vent and alarm system

• Continuous equipment management by alarm list record

|

| Convenience |

• Control system controls all operations after putting material

• Add sample tray according to customer requirements |

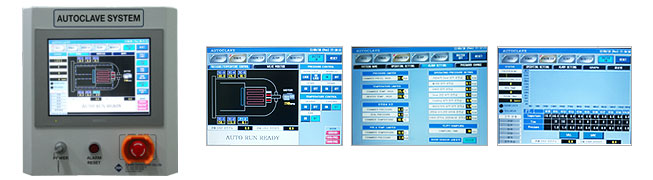

| Control System |

• Convenient touch screen

• Accurate test by automatic system |

|

|

| |

Process Variable of Autoclave Process Variable of Autoclave |

| Constant Temperature |

• Minimize temperature departure by circulation fan.

• Constant temperature by an insulation |

| Pressure Accuracy |

| •

Automatic valve line minimize pressure departure within 1.5% |

| Calculating an output |

| • Reducing process time by the cooling system |

|

| |

Specification Specification |

| * HA 440 - 35 Series |

| Series |

Working Vessel

Internal Diameter |

Working Vessel

Distance

|

Temperature |

Pressure |

| HA-440-35L |

440

㎜ |

350

㎜ |

200 ℃ |

9 ㎏/㎠ |

| HA-440-35H |

440

㎜ |

350

㎜ |

200 ℃ |

20

㎏/㎠ |

|

| |

| * HA 440 - 53 Series |

| Series |

Working Vessel

Internal Diameter |

Working Vessel

Distance

|

Temperature |

Pressure |

| HA-440-53L |

440

㎜ |

530

㎜ |

200 ℃ |

9 ㎏/㎠ |

| HA-440-53H |

440

㎜ |

530

㎜ |

200 ℃ |

20

㎏/㎠ |

|

| |

| * HA 440 - 63 Series |

| Series |

Working Vessel

Internal Diameter |

Working Vessel

Distance

|

Temperature |

Pressure |

| HA-440-63L |

440

㎜ |

630

㎜ |

200 ℃ |

9 ㎏/㎠ |

| HA-440-63H |

440

㎜ |

630

㎜ |

200 ℃ |

20

㎏/㎠ |

|

* Design and manufacture according to ASME, KGS and KOSHA

* Additional options are available such as sample tray and cart

|

| ※ Please contact our sales team to inquire about other specification |

| |

Technical sales team : +82-42-931-6100 (Ext. 1) |

|

|

| |