|

| |

| Home > System > Autoclave > Laminating Autoclave > GA series |

|

Autoclave |

Laminating Autoclave - GA Series [Overview] Laminating Autoclave - GA Series [Overview] |

|

| |

|

| |

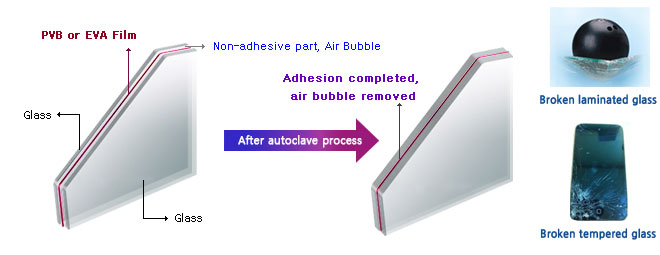

GA series (Glass Laminating Autoclave) is appropriate for removing air bubbles, heat treatment of glass surface and stress relief of products. In general, glass is divided into 3 types as follows: Laminated glass, Pair glass, and Tempered glass.

Laminated glass consists of two layers of glass with a layer of film bonded together in high pressure and high temperature. Although the glass may break, the laminated glass fragments remain firmly bonded to the interlayer, minimizing the risk of injuries.

Pair glass just consists of 2 layers of glasses without film. Pair glass has an efficiency of insulation by a gap between glasses.

Tempered glass is manufactured through a process of extreme heating and rapid cooling, making it harder than normal glass. Tempered glass shatters into oval-shaped pebbles when broken, therefore there are no sharp edges that can pose a danger.

Ilshin Autoclave Co. Ltd has ASME Pressure vessel manufacturing certification stamps (U1, U2, U3), manufactures equipment according to ASME standards ensuring high safety and air tightness.

Ilshin Autoclave Co. Ltd designs the equipment with multiple options such as Magnedrive to maintain constant temperature, cooling coil for rapid cooling, automatic opening / closing cover, perfect insulation and heating for controlling temperature departure, automatic valve line for controlling pressure and multi-safety system.

Please refer to Options & Accessories for various options according to the purpose of use. |

|

| |

|

| |

Principle and Applications of Gass Laminating Principle and Applications of Gass Laminating |

|

| |

Options & Accessories Options & Accessories |

|

| |

Products Model Products Model |

|

| |

|

|