|

|

| |

| Home > Research Center > Sample tests > Supercritical Fluid |

|

Research Center |

Sample Tests - Supercritical Fluid Sample Tests - Supercritical Fluid |

|

| Extractor |

- Volume: 300ml (basket),

- Max. Woking Press.& Temp. : 500bar , 80℃ |

| Separator |

- Volume : 300ml (2ea)

- Max. Woking Press.& Temp. : 100 bar , 80℃

|

| CO2 Flow rate |

- 70 ml/min |

| Co-Solvent

Flow rate |

- Max. 24ml/min < max. 350bar> |

|

|

|

- • Materials have to be dried because moisture decrease extraction efficiency. (ex. Freeze drying, hot air drying)

• Small particles more efficient for extraction because of high contact ratio with CO₂

• If you want to use cosolvents (ethanol, methanol, water, or organic solvent), please let us know in advance.

|

| |

The principle of process The principle of process |

|

| <More Info> |

Examples Examples |

| * Supercritical oil extraction |

|

| Examples |

Condition |

Examples |

Condition |

| Sesame |

Pressure: 300 ~ 500 bar

Temp.: 40 ~ 60℃ |

Peanut |

Pressure: 300 ~ 450 bar

Temp.: 50 ~ 70℃ |

| Corn germ

|

Pressure: 300 ~ 500 bar

Temp.: 30 ~ 50℃ |

Castor oil |

Pressure: 300 ~ 450 bar

Temp.: 50 ~ 70℃ |

| Soybean oil

|

Pressure: 200 ~ 350 bar

Temp.: 40 ~ 60℃ |

Grape seed |

Pressure: 300 ~ 500 bar

Temp.: 30 ~ 50℃ |

| Yu-chae(flower)

seed |

Pressure: 300 ~ 450 bar

Temp.: 40 ~ 50℃ |

Coffee |

Pressure: 200 ~ 350 bar

Temp.: 40 ~ 60℃

|

| Sunflower seed |

Pressure: 300 ~ 450 bar

Temp.: 40 ~ 50℃ |

Fish oil

|

Pressure: 200 ~ 400 bar

Temp.: 50 ~ 60℃

|

| Paprika |

Pressure: 150 ~ 350 bar

Temp.: 40 ~ 50℃ |

Coriandor seed |

Pressure: 200 ~ 300 bar

Temp.: 35 ~ 45℃

|

| Cotton seed |

Pressure: 450 ~ 600 bar

Temp.: 80 ~ 100℃ |

Coriandor seed |

Pressure: 100 ~ 150 bar

Temp.: 40 ~ 50℃ |

|

| |

| Ingredients extraction |

|

| Turmeric, yolk, herb, mulberry, iris, thyme, cactus, rubus seed, rice germ, citron, green tea, mustard, ginger, ginseng etc. |

| |

| * The others |

|

| Process |

Process Principle |

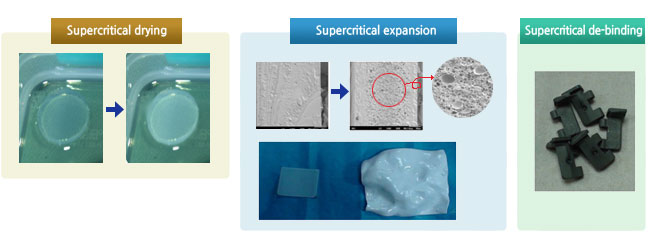

| Supercritical drying |

Remove moisture from material by supercritical CO₂

(ex. Drying aerosol by supercritical drying system : make transparent aerosol by high porosity and enable maintaining shape of material because prevent shrinkage and cracking) |

| Supercritical expansion |

Expansion molding technology without blowing agent in a short time by using supercritical CO₂ solvent

(Light-weight, absorbency, cost reduction) |

| Supercritical de-binding |

De-binding process of PIM(Powder Injection Molding).

Supercritical CO₂ is appropriate for de-binding system because it diffuses quickly and has low surface tension, which facilitates quick infiltration to micropores |

|

|

| |

|