| |

| |

| Home > System > High Pressure Reactor > Special Purpose Reactor > Polymerization Reactor |

|

High Pressure Reactor |

Special Purpose Reactor - Polymerization Reactor [Overview] Special Purpose Reactor - Polymerization Reactor [Overview] |

|

|

| |

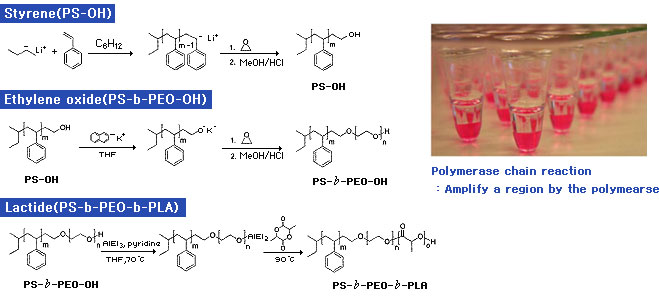

| Polymerization is a process of reacting monomer molecules together in a chemical reaction to form polymer chains. There are many forms of polymerization such as condensation polymer, addition polymer and copolymerization.

Ilshin Autoclave's Polymerization System is used for various polymerizations and performs accurate process.

Ilshin Autoclave Co.,Ltd obtained ASME pressure vessels certification of design & manufacturing, also have Korea Gas Safety Corporation and The Korea Occupational Safety and Health Agency certification so can ensure safety.

|

|

| |

|

| |

Classification of Polymerization Classification of Polymerization |

| Condensation Polymerization |

Condensation polymerization releasing small molecules as by-products such as water or methanol. Because this reaction resulting loss of small molecules which is often water, it’s also called dehydration polymerization. Concentrated Sulfuric Acid is used to process to accelerate reaction. Peptide binding and Ester binding is a typical example of condensation polymerization.

Ex) polyamide, polyester, urethane, bakelite |

| |

| Addition Polymerization |

Addition polymerization is a reaction, where many monomer bond together via rearrangement of bonds without the loss of any monomers. This occur in different ways which may be through free radical polymerization, cationic polymerization, anionic polymerization andcoordination polymerization.

Ex) PVC, polyethylene, polystyrene |

| |

| Copolymerization

|

| Copolymerization is a reaction derives polymer from 2 (or more) monomeric species, as opposed to a homopolymer where only one polymer is used. Common examples of this is a rubber using butadiene and styrene. It's widely used in chemical industry and fiber industry. |

| |

| Coordination Polymerization |

| Coordination Polymerization is a reaction in which monomer adds to growing macromolecule through an organometallic active center. Coordination type polymers are also stereoregular and can be isotactic or syndiotactic instead of just atactic. |

|

| |

Polymerization Polymerization |

|

| |

Pros and Cons of Polymerization Pros and Cons of Polymerization |

| Polymerization used in industry is classified as follow : bulk polymerization, solution polymerization, suspension polymerization, emulsion polymerization. Refer to the following table for properties of each methods. |

| |

Pros |

Cons |

Examples |

Bulk

Polymerization |

Simple process and derives macromolecules with high purity |

Hart to control exothermicity and high viscosity occurs.

|

-Continuous polymerization of styrene.

- Casting of methacrylate plate

- Continuous polymerization of polyvinyl |

Suspension

Polymerization |

Easy heat dissipation and derives macromolecules with low viscosity available as it is. |

This reaction needs cleaning and dehydration. Polymer cogulation can occur, and purity of polymer is getting low due to pollution by addictive. |

- Adhesives made from polyvinyl acetate

- Rubber made from polypropylene and polybutadiene. |

Solution

Polymerization |

Easy heat dissipation and derives macromolecules with low viscosity available in solution. |

The solvent for reaction is expensive, hard to remove solvent completely, and chain transfer reaction with solvent can occur. |

Beads, pvc powder made from foamed polyethylene, polystyrene, PMMS. |

Emulsion

Polymerization |

Easy heat dissipation and derives macromolecules with low viscosity available in emulsion. This is suitable for mucoadhesive polymers. |

Purity of polymer is getting low due to emulsifier and other addictives |

- Polyvinyl, polyvinyl acetate, polystyrene

- Resin finishing agent for SBR, NBR, concrete |

|

| |

Benefits of Ilshin Autoclave's Polymerization Reactor Benefits of Ilshin Autoclave's Polymerization Reactor |

| Safety |

• Design and manufacture according to ASME(American Society of Mechanical Engineer), pressure vessel standards.

• Design and manufacture according to KGS and KOSHA. |

| Accurate equipment |

• Improve process time and equipment efficiency by installation of heater

• Maintain constant temperature by internal/external insulation

• Improve safety through the multi-safety devices |

| Customized engineering |

• A variety of types and specification for customer

• Different types of research are available by various additional components. |

| Easy maintenance |

• A variety of measurements facilitate analyzing operating conditions

• Easy assembly/disassembly and clean up

• Quick response to customer request by customer service team. |

|

| |

Products Products |

|

|

| |

|