| |

| |

| Home > System > Supercritical Fluid System > Supercritical Carbon Dioxide (CO2) >

Supercritical Making

Nanoparticle System |

|

Supercritical Fluid System |

Supercritical Making

Nanoparticle System Supercritical Making

Nanoparticle System |

|

|

| |

Principle Principle |

| Supercritical fluid precipitation processes can produce a narrow particle size distribution. A gas becomes a supercritical fluid above a critical point, at a certain temperature and pressure. SCFs possess properties that are intermediate between liquids and gases. Generally CO is used because of its relatively mild supercritical conditions. Moreover, it is inexpensive, non-toxic, non-corrosive and not explosive or flammable. A possible refinement of the supercritical fluid technology involves the stirring of surfactants with an aqueous metal salt solution in supercritical CO. This process leads to the formation of microemulsions, which can be viewed as potential nanoreactors for synthesizing extremely homogeneous nanoparticles |

| |

Method Method |

| 1. RESS (Rapid Expansion of Supercritical Solutions) |

RESS consists of the saturation of the supercritical fluid with a solid substrate; then, the depressurization of the solution through a heated nozzle into a low pressure chamber produces a rapid nucleation of the substrate in form of very small particles that are collected from the gaseous stream. The morphology of the resulting solid material, crystalline or amorphous, depends on the chemical structure of the material and on the RESS parameters(temperature, pressure drop, impact distance of the jet against a surface, nozzle geometry, etc.) The very fast release of the solute in the gaseous medium should assure the production of very small particles. This process is particularly attractive due to the absence of organic solvents.

|

|

| |

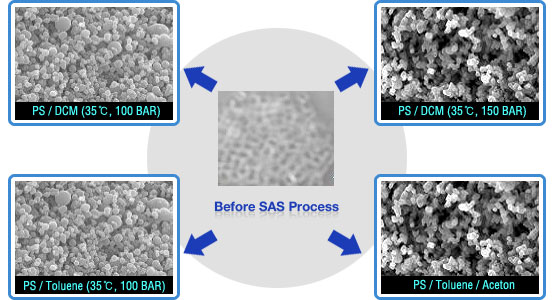

| 2. SAS (Supercritical Fluid Anti-Solvent) |

SAS has been proposed using various acronyms; but, the process is substantially the same in all the cases. A liquid solution contains the solute to be micronized; at the process conditions, the supercritical fluid should be completely miscible with the liquid solvent; whereas, the solute should be insoluble in the SCF. Therefore, contacting the liquid solution with the SCF induces the formation of a solution, producing super-saturation and precipitation of the solute.

|

|

| |

| 3. ASES (Aerosol Solvent Extraction System) |

ASES process involves jet break-up of the drug/polymer solution as fine droplets into compressed carbon dioxide through an atomization nozzle. It is expected that the particle size/morphology and crystallinity of solid dispersion could be controlled by changing temperature/pressure during ASES process, leading to improve solubility and dissolution rate.

|

|

|

| |

4. SEDS (Solution Enhanced Dispersion by Supercritical Fluids) |

| The general principle is the same as that for SAS, AESE process. The essential difference is related to the way of introducing the different phases ; in SEDS, a coaxial nozzle is used. |

|

| |

| 5. PGSS (Particles from Gas Saturated Solutions) |

| Using the PGSS process for the production of composites, a shell material is filled in and molten in vessel. The shell material is premixed with the emulsifier. The liquid is filled in vessel. The materials are pressurized and dosed to a mixing system using two high pressure pumps. In the mixing system the two substances are mixed and homogenized. A supercritical fluid (CO2) is added and partly dissolved in the formed emulsion. In the mixing system micro droplets of the core material are dispersed in the liquefied shell material. The dispersion is expanded to ambient pressure through a nozzle into a spray tower. Fine droplets are formed by expansion. Simultaneously the drops are cooled by the expanding gas (Joule-Thomson effect). The shell material solidifies and forms a cover around the micro liquid drops, generating a powderous composite. |

|

|

|

| |

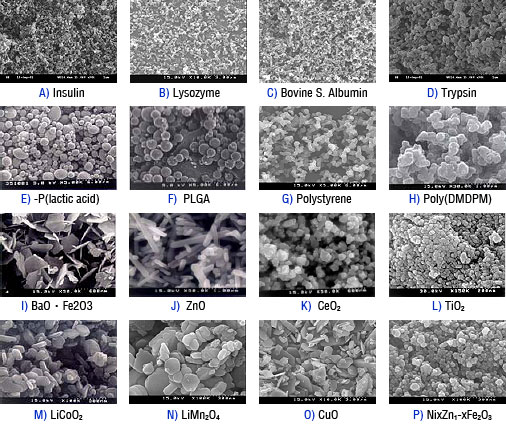

Nanoparticle by supercritical Nanoparticle by supercritical |

|

| |

|

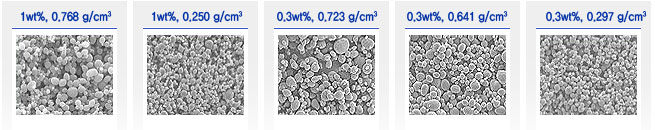

| Available to control particle size by adjusting temperature and pressure of anti solvent. |

| |

Poly(L-lactide) Poly(L-lactide) |

|

| |

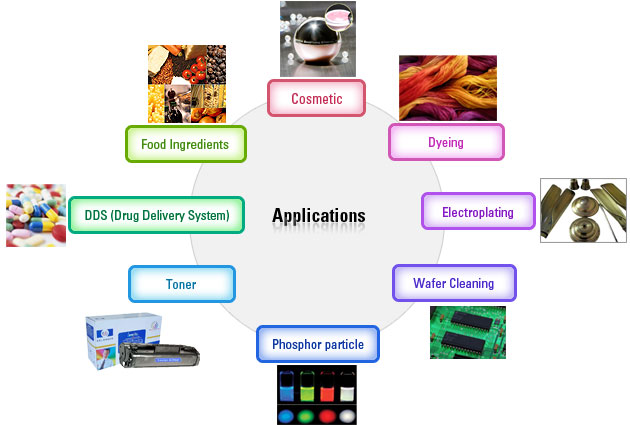

Application Application |

|

| |

Feature of nanoparticle by supercritical Feature of nanoparticle by supercritical |

| Safety |

| • Design by ASME, KGS, KOSHA |

| Accurate equipment |

• Stability by circulating system of heating carrier

• Completed insulation

• Multi Safety devices |

| Customized engineering |

• Convenient quick clamp type

• Various specification for customer's needs

• Available multipurpose test

• Precise measuring & ease control system.

|

| Easy Maintenance |

• Easy for monitoring the full operating status by various sensor of diagnostics.

• Easy to assemble and disassemble for cleaning and maintenance. |

|

| |

Products Products |

|

| |

|

|