| |

| |

| Home > System > High Pressure Reactor > Special Purpose Reactor > Hydrothermal Reactor |

|

High Pressure Reactor |

Special Purpose Reactor - Hydrothermal Reactor [Overview] Special Purpose Reactor - Hydrothermal Reactor [Overview] |

|

|

| |

| Hydrothermal synthesis means the techniques crystallizing substances such as metal salt, oxide, hydrate, or metal powders which depend on solubility, temperature, pressure and solute concentration in solution or suspension.

Liquid Phase Synthesis is synthesizing method in high temperature and pressure by using a water or aqueous solution. Mineralizer contributes the solubilization, accelerate nucleation of compound in liquid. Mineralizer not only just lowers the temperature but also generates compound selectively, so it is necessary for hydrothermal synthesis.

Ilshin Autoclave's Hydrothermal Synthesis system can perform hydrothermal synthesis of various materials. Most of powders are crystallized in 300, 85 /. Our equipments provide accurate temperature and pressure for process. Ilshin Autoclave Co.,Ltd obtained ASME pressure vessels certification of design & manufacturing, also have Korea Gas Safety Corporation and The Korea Occupational Safety and Health Agency certification so can ensure safety.

|

|

| |

|

| |

Classification of Hydrothermal Synthesis Classification of Hydrothermal Synthesis |

| Classification |

Features |

| Hydrothermal Crystallization |

Crystallize an amorphous substance or low crystalline in hot water. |

| Hydrothermal Precipitation |

Precipitate alcohols or salt by hydrolysis or neutralization in hydrothermal condition |

| Hydrothermal Reaction |

React solvent or solid in hydrothermal condition to generate new precipitation. |

| Hydrothermal Decomposition |

Decompose compounds in hydrothermal condition. |

| Hydrothermal Oxidation |

Oxidize metals by an water solution in high pressure and temperature. |

|

| |

The advantages of hydrothermal synthesis The advantages of hydrothermal synthesis |

| • Fast reaction and dispersion (It’s suitable for generating solid solution / compounds) |

| • Control pressure, temperature, solution, and addictives. |

| • Weaknesses of usual liquid phase synthesis (ex: co-precipitation, hydrolysis method) |

| |

| Weaknesses of usual liquid phase synthesis (ex: co-precipitation, hydrolysis method) |

- Non-uniformity when removing residual solvent

- Inhomogeneous crystallization

- Cause pollution / agglomeration when performs sintering or pulverization |

|

| |

Major materials using hydrothermal synthesis Major materials using hydrothermal synthesis |

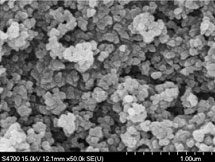

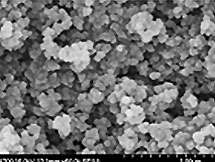

| * Hydrothermal Synthesis (BaTiO3)

|

1) Properties : High dielectric constant and thermostability → ferroelectricity, piezoelectricity

2) Applications : Capacitor, thermistor, sensor, communication filter, microwave filter, NVM(non-volatile memory),

DRAM(Dynamic Random Access Memory), heat detector, optical waveguide

3) Manufacturing process drawing of hydrothermal synthesis |

|

| 4) An analysis on properties of materials |

| Synthesis Method |

Firing temp.(°C) |

SSA(m2/g) |

SSA D(μ) |

X-ray D(μ) |

| Hydrothermal |

- |

8.5 |

0.12 |

0.09 |

| 400 |

8.2 |

0.12 |

- |

| 600 |

7.2 |

0.14 |

- |

| 800 |

6.0 |

0.16 |

- |

| Co-precipitation |

900 |

5.5 |

0.18 |

0.12 |

| 1000 |

4.6 |

0.22 |

0.13 |

| 1050 |

3.3 |

0.30 |

0.29 |

| Solid-state reaction |

1100 |

1.0 |

1.00 |

0.49 |

|

| |

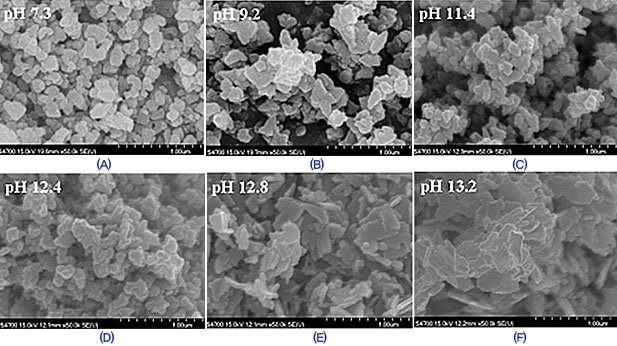

| * Hydrothermal Synthesis (ZnO) |

| |

|

| 1) Stirring speed :

zinc chloride (Zncl2) / zinc acetate (Zn(Ac)2) |

Starting material - Zinc chloride

ZnCl2 + 2NaOH → Zn(OH)2 + 2NaCl → ZnO + H2O + 2NaCl

Starting material - Zinc acetate

Zn(AC)2 + 2NaOH → Zn(OH)2 + 2NaAc→ ZnO + H2O + 2NaAc |

- Reaction temperature : 80

- Process time : 6 hours

- Precipitant : 1M NaOH (dropping 10ml/min)

- Stirring speed : 2000rpm |

| 2) Change of Zno according to Starting Material |

|

|

| Starting material : Zinc chloride |

Starting material : Zinc acetate |

|

| 3) Change of Zno according to Mole Concentration |

|

|

| (A) 0.2 M (B) 1 M (C) 2 M |

|

| 4) Change of Zno according to time |

|

| 5) Change of Zno according to temperature |

|

|

| 80 |

150 |

|

| 6) Change of Zno according to pH |

|

|

|

| |

Benefits of Ilshin Autoclave's Hydrothermal Synthesis Reactor Benefits of Ilshin Autoclave's Hydrothermal Synthesis Reactor |

| Safety |

• Design and manufacture according to ASME(American Society of Mechanical Engineer), pressure vessel standards.

• Design and manufacture according to KGS and KOSHA. |

| Accurate equipment |

• Improve process time and equipment efficiency by installation of heater

• Maintain constant temperature by internal/external insulation

• Improve safety through the multi-safety devices |

| Customized engineering |

• A variety of types and specification for customer

• Different types of research are available by various additional components. |

| Easy assembly/disassembly and clean up |

• A variety of measurements facilitate analyzing operating conditions.

• Easy assembly/disassembly and clean up |

|

| |

Products Products |

|

|

| |

|