|

| |

| Home > System > Autoclave > Composite Autoclave |

|

Autoclave |

Composite Autoclave - Overview Composite Autoclave - Overview

|

|

| |

|

|

What are composite materials?

Composite materials are binding materials in combination of different materials to maximize unique properties of materials. By combination of 2 or more materials, composites can offer tremendous advantages.

Hence, composites can overcome limitations of existing material or new material.

Composite materials have many benefits such as improvement of corrosion resistance, wear resistance, shock resistance, increase of fatigue life, light weight, and electric insulation. Composites are applied to aerospace industry as well as automobile industry, railroad, ship, construction, sporting goods and energy field.

Types of composite materials

• PMC : Polymer Matrix Composite(Glass, Aramid, Carbon)

• MMC : Metal Matrix Composite(car industry)

•

CMC : Ceramic Matrix Composite

|

|

| |

|

| |

Composite moulding technology Composite moulding technology |

| Autoclave moulding |

Robot hands for transport of LCD glass, CFRP support bar, industrial CFRP roller |

| Filament winding process |

Industrial roller, drive shaft, pipe, pressure vessel |

| Press moulding process |

Missile nozzle, bullet-proof |

| Resin transfer moulding process |

Various structure, automobile parts |

| Infusion moulding process |

Blade for wind generator, flame resistance for railroad interior material |

| Pultrusion |

FRP bar, beam |

|

| |

What is autoclave composite moulding? What is autoclave composite moulding? |

After laminated Prepreg with several shapes of molds, pack the whole of products with vacuum bag to block from the pressurizing part. When maintain vacuum inside, volatile components and air bubbles can be removed, and make accurate binding products. It facilitates manufacturing complicated shapes of products by isotropic pressure and the use of light-weight materials. It is appropriate for manufacturing aircraft, especially for 2nd structure. This process is used for wings of wind generator, marine sporting goods and automobile parts as well as aircraft parts.

Autoclave moulding process uses glass, carbon, and prepreg to make aerospace parts.

It’s usually used for single production, not for a mass production.

Autoclave can perform cooling, heating and vaccuming in the controlled temperature and pressure condition.

Ilshin autoclave’s Composite Autoclave is used for various shapes of composite mouding.

There are many vacuum lines to improve moulding efficiency. It can perform accurate temperature and pressure in order to improve efficiency, designed and manufactured according to ASME, KGS, and KOSHA. |

| |

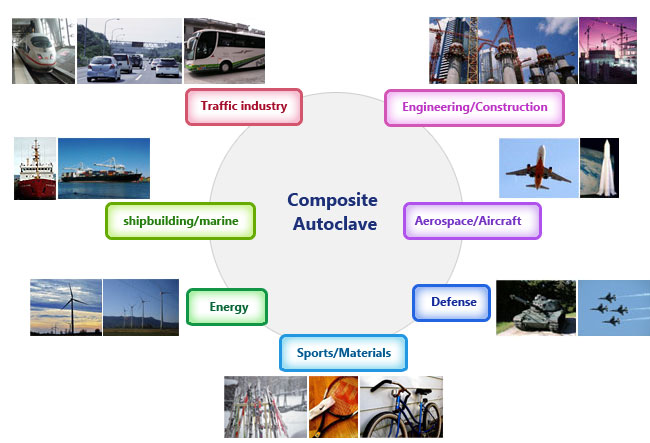

Applications Applications |

| Aerospace(aircraft parts), transportation(automobile, train parts), energy industy(wind generator wings), shipment, defense industry, sports, construction and many more applications. |

|

|

| ['Global Composite Market 2009-014; Markets and Technologies', Ludintel 2009 |

| |

Features of Ilshin Atuocalve’s Composite Autoclave Features of Ilshin Atuocalve’s Composite Autoclave |

| Safety |

• Design and manufacture according to ASME(American Society of Mechanical Engineer) pressure vessel standards.

• Design and manufacture according to KGS and KOSHA |

| Accurate equipment |

• Maintain constant temperature by installation of high pressure fan motor

• Maintain constant temperature by internal/external insulation

• Improve safety through the multi-safety devices |

| Customized engineering |

• A variety of models and specification for customer

• Different types of research are available by various additional components.

• Accurate measurement and simplification of control system enable more convenient research |

| Easy maintenance |

•A variety of measurements facilitate analyzing operating conditions.

•Easy assembly/disassembly and clean up

•

Quick response to customer request through customer service team. |

|

| |

Process Variable of Autoclave Process Variable of Autoclave |

| Constant Temperature |

| • Minimize temperature departure by circulation fan |

| Pressure Accuracy |

• Automatic valve line minimizes pressure departure within 1.5%

|

| Calculating an output |

• Calculate an amount of material at a time(product size / interior space)

• Calculate temperature, pressure and process time |

|

| |

Options & Accessories Options & Accessories |

|

| |

Products Products |

|

| |

|

|