PA 300 is used for small LCD module manufacturing process, to improve an efficiency of bonding process after laminating. It can maintain constant temperature and pressure, and pressurize 20,000 kgf.

We improved process efficiency by various shapes of molds.

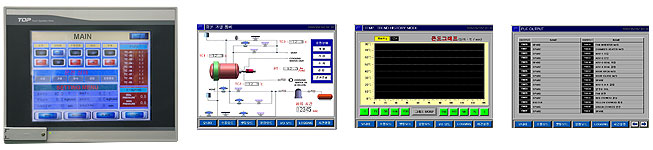

It’s appropriate for test and production by easy control system.

PA 300 is basically made from heat resisted coating carbon steel or stainless steel for chemical resistance and and using automatic opening / closing cover. It uses Multi-line Pressure System for safety and accurate air tightness during process. Pipe line consists of air pump, air vent, safety vent and thermocouple. Additional options are also available such as cooling coil for rapid cooling and automatic emission line for constant temperature and pressure. |

|

|

| |

Dimension Dimension |

| Working

Vessel Dia |

Ф300 ㎜ x 600 ㎜ |

| Working Temperature |

~ 200 ℃ |

| Working

Pressure |

20 ㎏/㎠ |

| Hydraulic

Pressing |

500 ~ 20,000 ㎏/㎠ |

| Temp.

& Pressure Deviation |

±1.5 (%) |

| Motor Rotational Speed |

~1,750 rpm |

| Dimension |

1,060 (W) X 1,400 (D) X 1,850(H) |

|

| |

Features of PA 300 Features of PA 300 |

| Safety |

• Design and manufacture according to ASME, KGS and KOSHA

• Multi-line Pressure Control System for safety

• Continuous management by alarm list record. |

| Control system |

• Controlling system controls all operations after material injection.

• Convenient cleaning by easy assembly / disassembly |

| Control system |

• Convenient touch screen

• Accurate testing by automatic system |

|

|

| |

Process Variable of Autoclave Process Variable of Autoclave |

| Constant Temperature |

| • Minimize temperature departure by circulation fan. |

| Pressure Accuracy |

| •

Automatic valve line minimize pressure departure within 1.5% |

| Calculating an output |

• Calculate an amount of material at a time(product size / interior space)

• Calculate temperature, pressure and process time. |

|

| |

Specification Specification |

| * PA 300 - 40 Series |

| Series |

Working Vessel

Internal Diameter |

Working Vessel

Distance

|

Temperature |

Pressure |

Pressing |

| PA300-40L |

300

㎜ |

400

㎜ |

200 ℃ |

9 ㎏/㎠ |

500 ~ 20,000

kgf |

| PA-300-40H |

300

㎜ |

400

㎜ |

200 ℃ |

20

㎏/㎠ |

|

| |

| * PA 300 - 60 Series |

| Series |

Working Vessel

Internal Diameter |

Working Vessel

Distance

|

Temperature |

Pressure |

Pressing |

| PA300-60L |

300

㎜ |

600

㎜ |

200 ℃ |

9 ㎏/㎠ |

500 ~ 20,000

kgf |

| PA300-60H |

300

㎜ |

600

㎜ |

200 ℃ |

20

㎏/㎠ |

|

| |

| * PA 300 - 90 Series |

| Series |

Working Vessel

Internal Diameter |

Working Vessel

Distance

|

Temperature |

Pressure |

Pressing |

| PA300-90L |

300

㎜ |

900

㎜ |

200 ℃ |

9 ㎏/㎠ |

500 ~ 20,000

kgf |

| PA300-90H |

300

㎜ |

900

㎜ |

200 ℃ |

20

㎏/㎠ |

|

* Design and manufacture according to ASME, KGS and KOSHA

* Additional options are available such as sample tray and cart

|

| ※ Please contact our sales team to inquire about other specification |

| |

Technical sales team : +82-42-931-6100 (Ext. 1) |

|

|

| |