|

| |

| Home > System > Autoclave > Composite Autoclave > CMAM series |

|

Autoclave |

Composite Autoclave - CMAP series Composite Autoclave - CMAP series

|

|

| |

|

| |

CMAP series is an autoclave for large composite components, used for aerospace industry like aileron and car industry like bumper. Vacuum line is connected to remove impurity before molding. In the case of pressurizing for molding, CMAS series maintain constant pressure and temperature, to perform process in an optimum condition.

Ilshin Autoclave has ASME Pressure vessel manufacturing certification stamps(U1, U2, U3), manufactures equipment with safety and air tightness by process according to ASME regulations.

such as vacuum line for improving efficiency of molding products, use of Magnedrive to maintain constant temperature, installing cooling coil for rapid cooling, automatic opening and closing of clamp cover, perfect insulation and heating for controlling temperature departure, automatic valve line for controlling pressure and multi-safety system.

various options according to the purpose of use are available, please refer to Options & Accessories tap. |

|

| |

|

| |

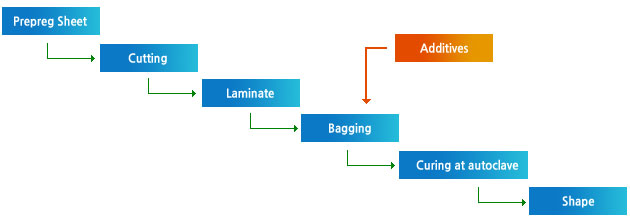

Composite Autoclave Moulding Process Composite Autoclave Moulding Process |

|

| |

Composite Autoclave Moulding Lamination Composite Autoclave Moulding Lamination |

| |

|

| |

Laminated molding & Bagging

• Prepregs + additive + sub-base material

• Reduce pressure to remove air bubbles when laminate 2~3 prepregs |

| |

Features of Composite Autoclave Features of Composite Autoclave |

| Safety |

• Design and manufacture according to ASME, KGS and KOSHA

• Multi-line Pressure Control System for safety

• Continuous management by alarm list record |

| Convenience |

• Minimize equipment size for efficient space use and application in various conditions.

• Controlling system controls all operations after putting material.

• Convenient cleaning by easy assembly / disassembly |

| Controlling system |

• Control system using touch screen

• Accurate testing by automatic system |

|

| |

Autoclave process variables Autoclave process variables |

| Constant temperature |

| • Minimize temperature departure by installing circulation fan. |

| Pressure Accuracy |

•

Automatic valve line maintain pressure departure within 1.5%

|

| Production |

| •

Sample trays increase production |

|

| |

Specification Specification |

| * CMAP 3000 Series |

| Series |

Working Vessel

Internal Diameter |

Working Vessel

Distance

|

Temperature |

Pressure |

| CMAP-3000-5000L |

3,000

㎜ |

5,000

㎜ |

200 ℃ |

9 ㎏/㎠ |

| CMAP-3000-5000H |

3,000

㎜ |

5,000

㎜ |

200 ℃ |

20

㎏/㎠ |

| CMAP-3000-7000L |

3,000

㎜ |

7,000

㎜ |

200 ℃ |

9 ㎏/㎠ |

| CMAP-3000-7000H |

3,000

㎜ |

7,000

㎜ |

200 ℃ |

20

㎏/㎠ |

| CMAP-3000-10000L |

3,000

㎜ |

10,000

㎜ |

200 ℃ |

9 ㎏/㎠ |

| CMAP-3000-10000H |

3,000

㎜ |

10,000

㎜ |

200 ℃ |

20

㎏/㎠ |

|

| |

| * CMAP 3500 Series |

| Series |

Working Vessel

Internal Diameter |

Working Vessel

Distance

|

Temperature |

Pressure |

| CMAP-3500-5000L |

3,500

㎜ |

5,000

㎜ |

200 ℃ |

9 ㎏/㎠ |

| CMAP-3500-5000H |

3,500

㎜ |

5,000

㎜ |

200 ℃ |

20

㎏/㎠ |

| CMAP-3500-7000L |

3,500

㎜ |

7,000

㎜ |

200 ℃ |

9 ㎏/㎠ |

| CMAP-3500-7000H |

3,500

㎜ |

7,000

㎜ |

200 ℃ |

20

㎏/㎠ |

| CMAP-3500-10000L |

3,500

㎜ |

10,000

㎜ |

200 ℃ |

9 ㎏/㎠ |

| CMAP-3500-10000H |

3,500

㎜ |

10,000

㎜ |

200 ℃ |

20

㎏/㎠ |

|

* Design and manufacture according to ASME, KGS and KOSHA

* Sample tray and cart are additional options.

|

| ※ Please contact our sales team to inquire about other specification |

| |

Technical sales team : +82-42-931-6100 (Ext. 1) |

|

|

|

| |

|

|