| SCECO Series is continuous type of Supercritical Polymer Foaming system. It mainly consist of polymer extrusion, injection and synthesis reactor. Put some raw material and water, surface active agent, adjust pressure and temperature, and then inject CO₂to get supercritical state. SCECO Series conforms with ASME CODE rigidly which ensure the safety. |

|

| |

|

Dimension Dimension |

| Extraction Vessel |

1ℓ x 1 set

Max. Working Condition : 420㎏/㎠ at 80℃ |

| Separate Vessel |

0.5ℓ x 1 set |

| CO2 Storage Vessel |

2ℓ x 1 set |

| CO2 High Pressure Pump |

Max. Flow Rate : 100㎖

/min |

| CO2 Gas Booster System |

Min. Pressure (1 step) : 50 ㎏/㎠ |

| Temperature Utility |

Chiller & Heating Bath System |

| Control System |

Electric Panel System |

|

| |

|

Dimension Dimension |

| Extraction Vessel |

2ℓ x 1 set

Max. Working Condition : 500㎏/㎠ at 80℃ |

| CO2 Heating Bath |

10ℓ x 1 set |

| CO2 Gas Booster System |

Min. Pressure (1 step) : 50㎏/㎠ |

| Temperature Utility |

Chiller & Heating Bath System |

| Control System |

Touch Panel Type |

| Structure |

Packing Type |

|

| |

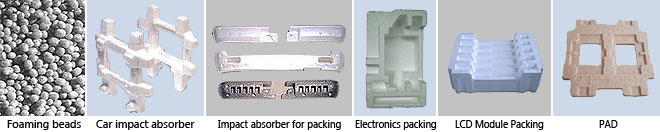

Application Application |

|

| |

SCEBA SCEBA |

| Safty |

• Design based on ASME

• Certified by KGS, KOSHA

• Safety device

• Convenience maintenance through the alarm list |

| Convenience |

• Easily to close by quick clamp type for high pressure

• Convenience to check operational status by measuring instrument

• Easy for assembly and disassembly |

| Control system |

• Touch screen to control & monitor

• DAQ and Auto system control |

|

| |

Process variables Process variables |

| Temperature |

• Stability by circulating system of heating carrier

• Cooling and heating graded control |

| Pressure |

• Accuracy 1.5% by controlling back pressure regulator

• Accurate back pressure regulator |

| TEST |

| • Various test according to different test materials |

|

| |

Specification Specification |

| * SCECO 05 Series |

| Series |

Extractor Volume |

Pressure |

Temperature |

Heating Bathe |

| SCECO05-150 |

0.5ℓ |

350 ㎏/㎠ |

80 ℃ |

3ℓ |

| SCECO05-350 |

0.5ℓ |

350 ㎏/㎠ |

80 ℃ |

3ℓ |

| SCECO05-600 |

0.5ℓ |

600 ㎏/㎠ |

80 ℃ |

3ℓ |

|

| |

| * SCECO 10 Series |

| Series |

Extractor Volume |

Pressure |

Temperature |

Utility Unit |

| SCECO10-150 |

1ℓ |

150 ㎏/㎠ |

80 ℃ |

5ℓ |

| SCECO10-350 |

1ℓ |

350 ㎏/㎠ |

80 ℃ |

5ℓ |

| SCECO10-600 |

1ℓ |

600 ㎏/㎠ |

80 ℃ |

5ℓ |

|

| |

| * SCECO 20 Series |

| Series |

Extractor Volume |

Pressure |

Temperature |

Utility Unit |

| SCECO20-150 |

2ℓ |

150 ㎏/㎠ |

80 ℃ |

10ℓ |

| SCECO20-350 |

2ℓ |

350 ㎏/㎠ |

80 ℃ |

10ℓ |

| SCECO20-600 |

2ℓ |

600 ㎏/㎠ |

80 ℃ |

10ℓ |

|

| |

| * SCECO 30 Series |

| Series |

Extractor Volume |

Pressure |

Temperature |

Utility Unit |

| SCECO30-150 |

3ℓ |

150 ㎏/㎠ |

80 ℃ |

15ℓ |

| SCECO30-350 |

3ℓ |

350 ㎏/㎠ |

80 ℃ |

15ℓ |

| SCECO30-600 |

3ℓ |

600 ㎏/㎠ |

80 ℃ |

15ℓ |

|

| |

| * SCECO 50 Series |

| Series |

Extractor Volume |

Pressure |

Temperature |

Utility Unit |

| SCECO50-150 |

5ℓ |

150 ㎏/㎠ |

80 ℃ |

25ℓ |

| SCECO50-350 |

5ℓ |

350 ㎏/㎠ |

80 ℃ |

25ℓ |

| SCECO50-600 |

5ℓ |

600 ㎏/㎠ |

80 ℃ |

25ℓ |

|

* Obtained safety certification

* Different material is possible

* Opening type or Packing type can be decided by user

* Utility Unit (Heating & Cooling System, Pressure Control etc.) is optional |

| ※ Please contact our sales team to inquire about other specification |

| |

Technical sales team : +82-42-931-6100 (ext. 1) |

|

|

| |