| Supercritical Polymer Foaming system is a physical foaming type not utilizing chemical agent such as Polypropylene. SCEBA Series is batch type system. Into the reactor, put some Expanded Polypropylene Beads(EPP Beads) and get Expanded Beads with instant expansion.

Put some raw material and water, surface active agent, adjust pressure and temperature, and then inject CO2 to get supercritical state.

|

|

| |

|

Dimension Dimension |

| Extraction Vessel |

1ℓ x 2 set

Max. Working Condition : 500 ㎏/㎠ at 200 ℃ |

| CO2 Gas Booster System |

ISA-GB11-100 |

| Temperature Utility |

Heating Jacket System |

| Control System |

Electric Box Type |

|

| |

|

Dimension Dimension |

| Extraction Vessel |

100 ℓ x 1 set

Max. Working Condition : 100 ㎏/㎠ at 80 ℃ |

| Separate Vessel |

30 ℓ x 1 set |

| CO2 Storage Vessel |

150 ℓ x 1 st |

| CO2 Gas Booster System |

2 set

Max. Flow Rate : 1 ℓ/min |

| Heating Utility |

Pre-heater (2set) & Heating System |

| Cooling Utility |

Condenser (2set) & Cooling System |

| Recycle System |

Filtering Vessel System |

| Control System |

Electric Both System |

| * Auto Moving Cover & Clamp ( Clutch Clamp Type) |

|

| |

Features of Raw Material Features of Raw Material |

• Spherical particle foam

• Pure PP ingredient

• Density 20~60g/l

• Density 20~60g/l after foaming

• Color: black, grey and white

• Special coloring is possible |

| |

Features of Material after foaming Features of Material after foaming |

• No foaming agent, one-component CFC-FREE foam

• High mechanical strength, flexibility

• From - 40℃ to 130℃ (cold and heat resistant)

• Excellent resilience after impact

• Hardness and tactile can be selected

• Unabsorbed and floatable

• Easy workability (cutting, adhesive available)

• Good thermal insulation performance

• 100% recycling

• Non-toxic and thermal disinfection possible

• No surface friction noise, EPS

• Resistance to flame

• Chemical, oil, water and weather resistance

|

| |

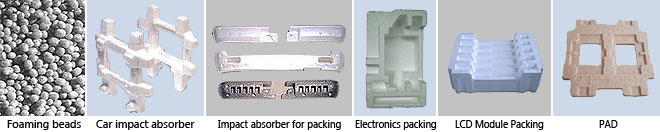

Application Application |

|

| |

SCEBA SCEBA |

| Safty |

• Design based on ASME

• Certified by KGS, KOSHA

• Safety device

• Convenience maintenance through the alarm list̷ |

| Convenience |

• Easily to close by quick clamp type for high pressure

• Convenience to check operational status by measuring instrument

• Easy for assembly and disassembly |

| Control system |

• Touch screen to control & monitor

• DAQ and Auto system control |

|

| |

Process variables Process variables |

| Temperature |

• Stability by circulating system of heating carrier

• Cooling and heating graded control |

| Pressure |

• Accuracy 1.5% by controlling back pressure regulator

• Accurate back pressure regulator |

| TEST |

| • Various test according to different test materials |

|

| |

Specification Specification |

| * SCEBA 03 Series |

| Series |

Reactor Volume |

Pressure |

Temperature |

Utility Unit |

| SCEBA03-150 |

0.3ℓ |

150 ㎏/㎠ |

80 ℃ |

N |

| SCEBA03-350 |

0.3ℓ |

350 ㎏/㎠ |

80 ℃ |

N |

| SCEBA03-600 |

0.3ℓ |

600 ㎏/㎠ |

80 ℃ |

N |

|

| |

| * SCEBA 05 Series |

| Series |

Reactor Volume |

Pressure |

Temperature |

Utility Unit |

| SCEBA05-150 |

0.5ℓ |

150 ㎏/㎠ |

80 ℃ |

N |

| SCEBA05-350 |

0.5ℓ |

350 ㎏/㎠ |

80 ℃ |

N |

| SCEBA05-600 |

0.5ℓ |

600 ㎏/㎠ |

80 ℃ |

N |

|

| |

| * SCEBA 10 Series |

| Series |

Reactor Volume |

Pressure |

Temperature |

Utility Unit |

| SCEBA10-150 |

1ℓ |

150 ㎏/㎠ |

80 ℃ |

N |

| SCEBA10-350 |

1ℓ |

350 ㎏/㎠ |

80 ℃ |

N |

| SCEBA10-600 |

1ℓ |

600 ㎏/㎠ |

80 ℃ |

N |

|

| |

| * SCEBA 100 Series |

| Series |

Extractor Volume |

Pressure |

Temperature |

Utility Unit |

| SCEBA100-150 |

10ℓ |

150 ㎏/㎠ |

80 ℃ |

1 set |

| SCEBA100-350 |

10ℓ |

350 ㎏/㎠ |

80 ℃ |

1 set |

| SCEBA100-600 |

10ℓ |

600 ㎏/㎠ |

80 ℃ |

1 set |

|

| |

| * SCEBA 500 Series |

| Series |

Extractor Volume |

Pressure |

Temperature |

Utility Unit |

| SCEBA500-150 |

50ℓ |

150 ㎏/㎠ |

80 ℃ |

1 set |

| SCEBA500-350 |

50ℓ |

350 ㎏/㎠ |

80 ℃ |

1 set |

| SCEBA500-600 |

50ℓ |

600 ㎏/㎠ |

80 ℃ |

1 set |

|

| |

| * SCEBA 1000 Series |

| Series |

Extractor Volume |

Pressure |

Temperature |

Utility Unit |

| SCEBA1000-150 |

100ℓ |

150 ㎏/㎠ |

80 ℃ |

2 set |

| SCEBA1000-350 |

100ℓ |

350 ㎏/㎠ |

80 ℃ |

2 set |

| SCEBA1000-600 |

100ℓ |

600 ㎏/㎠ |

80 ℃ |

2 set |

|

* Obtained safety certification

* Different material is possible

* Opening type or Packing type can be decided by user

* Utility Unit (Heating & Cooling System, Pressure Control etc.) is optional |

| ※ Please contact our sales team to inquire about other specification |

| |

Technical sales team : +82-42-931-6100 (ext. 1) |

|

|

| |