| SHS 10 is 10ℓ reactor, suitable for SHS of various materials. Terminal for electricity supply is connected to inside the reactor for self-propagating and sight glass is installed to the reactor. There is a vacuum line for optimum condition. This system facilitates self-propagating synthesis for various compounds of materials.

SHS 10 is made from stainless steel or carbon steel. Nozzle basically consists of injection line, emission line, safe vent and thermocouple. Magnetic bar and there are multiple options such as deep tube for gas injection during the process, and cooling coil for rapid cooling.

|

|

| |

|

| |

Dimension Dimension |

| Working Capacity |

10ℓ (Inside size :

φ

203.3 ㎜ X 380 ㎜) |

| Working Temp. |

~ 100 ℃ |

| Working Pressure |

200 ㎏/㎠ |

| Process Type |

Sight Glass Wiew Type |

| Material |

SUS304 / SNCM439 |

| Main Seal |

O-ring Seal |

| Closure Type |

Double Ended Screw |

* Main Reactor

* Powder Basket/ Electric Connector - 1set

*

Vacuum Pump/ Line - 1set |

|

| |

Features or SHS10 Features or SHS10 |

| Safety |

• Design and manufacture according to ASME U1, U2 pressure vessel standard

• Safety and accuracy by double control system for pressure.

• Assure safety and accuracy by double pressure control system.

• Continuous equipment management by alarm list record. |

| Convenience |

• Large workspace is compatible with various environmental conditions.

• Control system controls all operations after putting material.

• Convenient cleaning by easy assembly / disassembly |

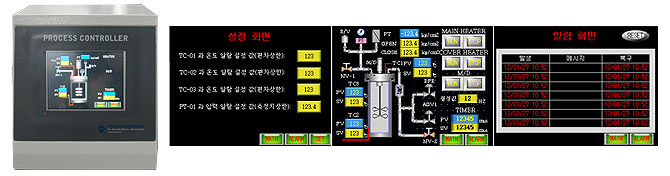

| Control System |

• Convenient touch screen

• Accurate testing by automatic system |

|

|

| |

Specification Specification |

| * SHS 10 Series |

| Series |

Liner Type |

Temperature |

Pressure |

View Zone |

Material |

| SHR 10-1001 |

10ℓ |

100 ℃ |

200

㎏/㎠ |

15 x 30 (D) |

SNCM |

| SHR 10-1002 |

10ℓ x 2 |

100 ℃ |

200 ㎏/㎠ |

15 x 30 (D) |

SNCM |

| SHR 10-1003 |

10 ℓ x 3 |

100 ℃ |

200 ㎏/㎠ |

15 x 30 (D) |

SNCM |

|

| |

| * SHS 20 Series |

| Series |

Liner Type |

Temperature |

Pressure |

View Zone |

Material |

| SHR 20-1001 |

20ℓ |

100 ℃ |

200

㎏/㎠ |

15 x 30 (D) |

SNCM |

| SHR 20-1002 |

20ℓ x 2 |

100 ℃ |

200 ㎏/㎠ |

15 x 30 (D) |

SNCM |

| SHR 20-1003 |

20 ℓ x 3 |

100 ℃ |

200 ㎏/㎠ |

15 x 30 (D) |

SNCM |

|

| |

| * SHS 30 Series |

| Series |

Liner Type |

Temperature |

Pressure |

View Zone |

Material |

| SHR 30-1001 |

30ℓ |

100 ℃ |

200

㎏/㎠ |

15 x 30 (D) |

SNCM |

| SHR 30-1002 |

30ℓ x 2 |

100 ℃ |

200 ㎏/㎠ |

15 x 30 (D) |

SNCM |

| SHR 30-1003 |

30 ℓ x 3 |

100 ℃ |

200 ㎏/㎠ |

15 x 30 (D) |

SNCM |

|

| |

| * SHS 40 Series |

| Series |

Liner Type |

Temperature |

Pressure |

View Zone |

Material |

| SHR 40-1001 |

40ℓ |

100 ℃ |

200

㎏/㎠ |

15 x 30 (D) |

SNCM |

| SHR 40-1002 |

40ℓ x 2 |

100 ℃ |

200 ㎏/㎠ |

15 x 30 (D) |

SNCM |

| SHR 40-1003 |

40 ℓ x 3 |

100 ℃ |

200 ㎏/㎠ |

15 x 30 (D) |

SNCM |

|

* Double electrical terminal can be connected.

*Sight glass is made from quartz, tempered glass, polycarbonate, or sapphire. |

| Please contact our sales team to inquire about other specification |

| |

Technical sales team : +82-42-931-6100 (Ext. 1) |

|

|