|

| Liquid CO Supply Pressure |

650 ~ 1100 psi

|

| Propellant Type |

CDA, N2, Ar, CO |

| Propellant Supply Pressure |

70~150 psi

|

| Propellant Temperature |

20~125

|

| Snow Tube

|

0.03 inch

|

| Cleaning Zone Dimension |

161214 inch

|

| HEPA System Temperature

|

50(max)

|

| CleanStation Dimension

|

26 x 22 x 28 inch |

|

|

|

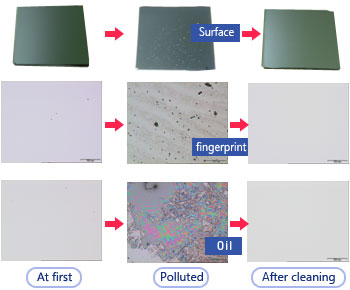

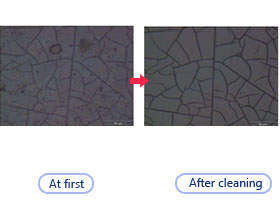

| Dry ice cleaning method is regarded as an alternative method for the existing cleaning methods because it is harmless to people and the environment and has a good cleaning efficiency. This method removes pollution by the crash of dry ice into material surface. In general, there are Pellet type and Snow type for this method.

Our Dry ice cleaning equipment is Snow type. |

| |

The principle of process The principle of process |

• Aerodynamic drag

• A crash energy of dry ice particles

• A solvency of dry ice particles

• Removal by thermophoresis |

| |

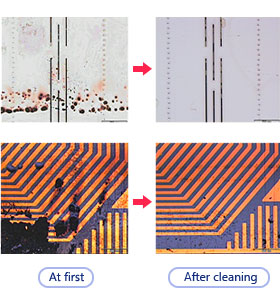

Examples Examples |

| * Wafer |

* Electronic parts |

|

|

| |

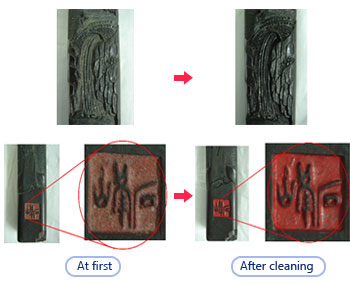

|

| * Stones |

* Woods |

|

|

|

| * In terms of stones / woods, the cleaning without surface damage is possible. |

| |

Applications Applications |

• An organic pollution on the surface

• Sticking pollution on the surface

• Metal, woods, stones and other many different materials.

• Precision parts, cultural assets

• Customized equipment for various other industries |