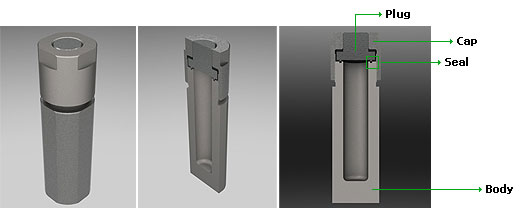

| PV 100 is Plug Closure Pressure Vessel which volume is 100ml. Firstly fasten the plug and then press cap or bolt to seal the cover. The basic material is chemically resistant Stainless Steel. If strong corrosion, resistant inner vessel can also be insert. Nozzle can be installed additionally and stirring device, temperature sensor, size of port is optional according to customer's request. |

|

| |

|

| |

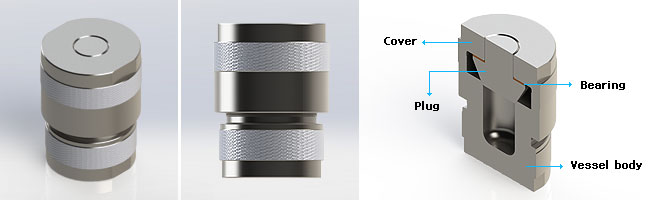

Structure of PV (Plug Closure Pressure Vessel) Structure of PV (Plug Closure Pressure Vessel) |

|

| |

Features of PV 100 Features of PV 100 |

• Plug presses seal (O-ring/Teflon) to make vessel closed

• Mini vessel(100~300ml) uses screw, above 300ml uses bolt

• Special material inner liner

• Material can be changed according to use and samples |

| |

Specification Specification |

| |

| Plug closure_Seal type : Surface type |

| |

| Model Number |

PV25 |

PV50 |

PV100 |

PV125 |

PV150 |

PV200 |

| Size |

25㎖ |

50㎖ |

100㎖ |

125㎖ |

150㎖ |

200㎖ |

| Nomal. temperature |

~ 300℃ |

| Normal. pressure |

~ 100 bar |

| Body material |

Stainless steel |

| Seal type |

Surface sealing |

| Closure style |

Plug closure |

| Vessel dimension(mm) |

Overall height |

104 |

156 |

145.9 |

166.9 |

176.9 |

210.9 |

| Max. O. D. |

65 |

65 |

95 |

95 |

95 |

95 |

| Inside dimension(mm) |

Inside diameter |

26.5 |

26.5 |

44.5 |

44.5 |

44.5 |

44.5 |

| Inside depth |

45.2 |

97.2 |

65.5 |

86.5 |

96.5 |

130.5 |

|

| |

Description Description |

| PV25 |

; ; |

| |

| PV50 |

; ; |

| |

| PV75 |

; ; |

| |

| PV100 |

; ; |

| |

| Please contact our sales team to inquire about other specification |

| |

Technical sales team : +82-42-931-6100 (Ext. 1) |

|

|