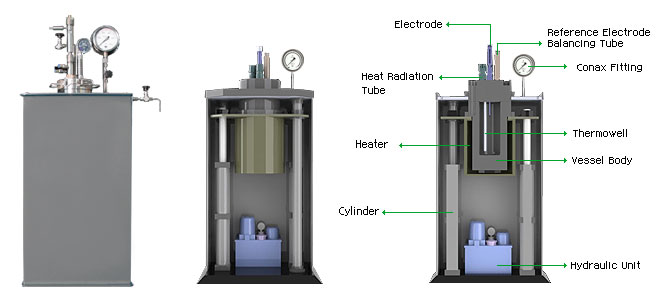

| BUD 2G is 2Gal(7,570㎖) reactor, suitable for various chemical reaction. The body of BUD1G can move up and down by pneumatic cylinder for user convenience. It is available to add agitator to accelerate reaction. BUD1G is basically made from stainless steel for chemical resistance, and the vessel is easily removable. It is able to apply SUS liner or Teflon liner according to purpose of research and corrosion resistance. Nozzle basically consists of injection line, emission line, safe vent and thermocouple. Magnetic bar and Magnetic Agitator facilitate stirring, to accelerate reaction |

|

| |

|

| |

Dimension Dimension |

| Working

Capacity |

2G(7,570㎖)

(Inside Size : Ф127 ㎜ X 610 ㎜) |

| Working

Temp. |

~ 350 ℃ |

| Working

Pressure |

~ 200 ㎏/㎠ |

| Body Up & Down |

Oil Pressure Cylinder |

| MD Rotational Speed |

~ 1750rpm |

| Heater Capacity |

4 kw |

| Dimension |

450(W) X 750(D) X 1,200(H) |

|

| |

Features of BUD2G Features of BUD2G |

| Safety |

• Design and manufacture according to ASME pressure vessel standard

•

Design and manufacture according to KGS & KOSHA

• Ensure safety by safety vent and alarm system.

• Continuous equipment management by alarm list record. |

| Convenience |

• Compact workspace is compatible with various environmental conditions

• Control system controls all operations after material injection.

• Convenient cleaning by easy assembly / disassembly |

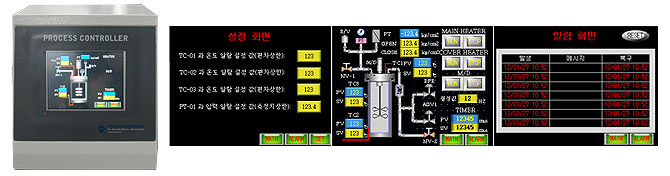

| Control system |

• Convenient touch screen

• Accurate testing by automatic system |

|

|

| |

Specification Specification |

| * BUD2G TO Series |

| Series |

Volume |

Temperature |

Pressure |

Seal Type |

| BUD2G-TOI |

2G (7.57ℓ)

|

150 ℃ |

20

㎏/㎠ |

O-ring |

| BUD2G-TOL |

2G (7.57ℓ) |

180 ℃ |

50 ㎏/㎠ |

O-ring |

| BUD2G-TOS |

2G (7.57ℓ) |

200 ℃ |

100 ㎏/㎠ |

O-ring |

| BUD2G-TOH |

2G (7.57ℓ) |

200 ℃ |

200 ㎏/㎠ |

O-ring |

|

* BUD2G-TO series is made from Teflon Liner because of corrosion

* Impeller and Thermowell processed Teflon Coating |

| |

| * BUD2G SO Series |

| Series |

Volume |

Temperature |

Pressure |

Seal Type |

| BUD2G-TOI |

2G (7.57ℓ) |

150 ℃ |

20

㎏/㎠ |

O-ring |

| BUD2G-TOL |

2G (7.57ℓ) |

180 ℃ |

50 ㎏/㎠ |

O-ring |

| BUD2G-TOS |

2G (7.57ℓ) |

200 ℃ |

100 ㎏/㎠ |

O-ring/Teflon |

| BUD2G-TOH |

2G (7.57ℓ) |

250 ℃ |

200 ㎏/㎠ |

O-ring/Teflon |

|

* BUD 2G-SO series is appropriate for a sample that has a few influences of corrosion, and using SUS liner for easy assembly/disassembly.

|

| |

| * BUD2G SM Series |

| Series |

Volume |

Temperature |

Pressure |

Seal Type |

| BUD2G-SMI |

2G (7.57ℓ) |

270 ℃ |

20

㎏/㎠ |

Metal |

| BUD2G-SML |

2G (7.57ℓ) |

300 ℃ |

50 ㎏/㎠ |

Metal |

| BUD2G-SMS |

2G (7.57ℓ) |

350 ℃ |

100 ㎏/㎠ |

Metal |

| BUD2G-SMH |

2G (7.57ℓ) |

350 ℃ |

200 ㎏/㎠ |

Metal |

|

* BUD1G – SM series has corrosion resistance, and using SUS liner for easy assembly/disassembly.

* Apply torque value by torque wrench.

|

| ※ Please contact our sales team to inquire about other specification |

| |

Technical sales team : +82-42-931-6100 (Ext. 1) |

|

|