| |

| |

| Home > System > Press > Isostatic Press > CIP >CIPL |

|

Press |

Cold Isostatic Press - CIPL Cold Isostatic Press - CIPL |

|

| |

|

| |

| CIPL Series is pilot scale system and the volume is from 2L to 10L. And the pressure can be changed from 2000 kg/c㎡(29,000psi) to 4000 kg/c㎡(58,000psi). The inner vessel material is Stainless Steel that can endure the high design pressure. 5 kg/c㎡ air is necessary for cover and pump's working. CIPS Series consists of three main parts: pump, pressure vessel and control system. And there is sensor and gauge to check the pressure. Also auto valves is installed that can be make operation easier. |

|

| |

|

| |

Dimension Dimension |

| Working Zone |

φ250mm x 400mm I.L |

| Internal Volume |

20ℓ |

| Max. Working Pressure |

3,000㎏/㎠ |

| Max. Working Temp. |

50 ℃ |

| Material |

Alloy steel |

| Closure Type |

Threadless Pin Closure |

| High Pressure Pump |

Air Driven Liquid Pump |

|

* Air Cylinder (Cover on/off) 1 set

* Reserovir Tank 20ℓ 1 EA

* Pressure Controller 1 EA |

| |

Features of CIPL Features of CIPL |

| Safety |

• Designed and manufactured according to ASME U1, U2 pressure vessel standard

• Appropriate seal type and material for high pressure

• Assure safety and accuracy by alarm system and other devices.

• Installed a valve for manual controlling |

| Convenience |

• Automatic valve for a cover lifting

• Digital indicator and gauge for accuracy

• Automatic system to maintain a constant pressure

• Compact workspace is compatible with various environmental conditions |

| Control system |

• Interlock setting ensure a safety

• Automatic system by PLC controlling |

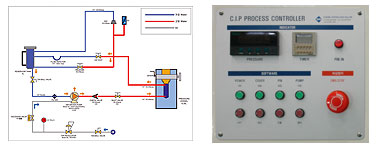

| * P&ID (Piping and Instrumentation Diagram) |

|

|

| |

Specification Specification |

| * CIP-L 20 Series |

| Series |

Max.

Pressure |

Internal

Diameter |

Internal

Length |

Volume |

Working

Media |

Material |

| CIP-L20-100-300 |

2,000 ㎏/㎠

|

φ 100 |

300 ㎜ |

2.3 ℓ |

Oil/

Water |

Stainless

Steel |

| CIP-L20-100-350 |

2,000 ㎏/㎠ |

350 ㎜ |

2.7 ℓ |

| CIP-L20-100-400 |

2,000 ㎏/㎠ |

400 ㎜ |

3.1 ℓ |

| CIP-L20-100-450 |

2,000 ㎏/㎠

|

450 ㎜ |

3.5 ℓ |

| CIP-L20-150-300 |

2,000 ㎏/㎠ |

φ 150 |

300 ㎜ |

5.3 ℓ |

| CIP-L20-150-350 |

2,000 ㎏/㎠ |

350 ㎜ |

6.1 ℓ |

| CIP-L20-150-400 |

2,000 ㎏/㎠

|

400 ㎜ |

7.0 ℓ |

| CIP-L20-150-450 |

2,000 ㎏/㎠ |

450 ㎜ |

7.9 ℓ |

| CIP-L20-200-300 |

2,000 ㎏/㎠ |

φ 200 |

300 ㎜ |

9.4 ℓ |

| CIP-L20-200-350 |

2,000 ㎏/㎠

|

350 ㎜ |

10.9 ℓ |

| CIP-L20-200-400 |

2,000 ㎏/㎠ |

400 ㎜ |

12.5 ℓ |

| CIP-L20-200-450 |

2,000 ㎏/㎠ |

450 ㎜ |

14.1 ℓ |

|

| |

| * CIP-L 30 Series |

| Series |

Max.

Pressure |

Internal

Diameter |

Internal

Length |

Volume |

Working

Media |

Material |

| CIP-L30-100-300 |

3,000 ㎏/㎠

|

φ 100 |

300 ㎜ |

2.3 ℓ |

Oil/

Water |

Stainless

Steel |

| CIP-L30-100-350 |

3,000 ㎏/㎠ |

350 ㎜ |

2.7 ℓ |

| CIP-L30-100-400 |

3,000 ㎏/㎠ |

400 ㎜ |

3.1 ℓ |

| CIP-L30-100-450 |

3,000 ㎏/㎠

|

450 ㎜ |

3.5 ℓ |

| CIP-L30-150-300 |

3,000 ㎏/㎠ |

φ 150 |

300 ㎜ |

5.3 ℓ |

| CIP-L30-150-350 |

3,000 ㎏/㎠ |

350 ㎜ |

6.1 ℓ |

| CIP-L30-150-400 |

3,000 ㎏/㎠

|

400 ㎜ |

7.0 ℓ |

| CIP-L30-150-450 |

3,000 ㎏/㎠ |

450 ㎜ |

7.9 ℓ |

| CIP-L30-200-300 |

3,000 ㎏/㎠ |

φ 200 |

300 ㎜ |

9.4 ℓ |

| CIP-L30-200-350 |

3,000 ㎏/㎠

|

350 ㎜ |

10.9 ℓ |

| CIP-L30-200-400 |

3,000 ㎏/㎠ |

400 ㎜ |

12.5 ℓ |

| CIP-L30-200-450 |

3,000 ㎏/㎠ |

450 ㎜ |

14.1 ℓ |

|

| |

| * CIP-L 40 Series |

| Series |

Max.

Pressure |

Internal

Diameter |

Internal

Length |

Volume |

Working

Media |

Material |

| CIP-L40-100-300 |

4,000 ㎏/㎠

|

φ 100 |

300 ㎜ |

2.3 ℓ |

Oil/

Water |

Stainless

Steel |

| CIP-L40-100-350 |

4,000 ㎏/㎠ |

350 ㎜ |

2.7 ℓ |

| CIP-L40-100-400 |

4,000 ㎏/㎠ |

400 ㎜ |

3.1 ℓ |

| CIP-L40-100-450 |

4,000 ㎏/㎠

|

450 ㎜ |

3.5 ℓ |

| CIP-L40-150-300 |

4,000 ㎏/㎠ |

φ 150 |

300 ㎜ |

5.3 ℓ |

| CIP-L40-150-350 |

4,000 ㎏/㎠ |

350 ㎜ |

6.1 ℓ |

| CIP-L40-150-400 |

4,000 ㎏/㎠

|

400 ㎜ |

7.0 ℓ |

| CIP-L40-150-450 |

4,000 ㎏/㎠ |

450 ㎜ |

7.9 ℓ |

| CIP-L40-200-300 |

4,000 ㎏/㎠ |

φ 200 |

300 ㎜ |

9.4 ℓ |

| CIP-L40-200-350 |

4,000 ㎏/㎠

|

350 ㎜ |

10.9 ℓ |

| CIP-L40-200-400 |

4,000 ㎏/㎠ |

400 ㎜ |

12.5 ℓ |

| CIP-L40-200-450 |

4,000 ㎏/㎠ |

450 ㎜ |

14.1 ℓ |

|

| |

| Please contact our sales team to inquire about other specification |

| |

Technical sales team : +82-42-931-6100 (Ext. 1) |

|

|

|

| |

|