PMR 1000 is 1000 (or more than) reactor for production, installed as a plant scale and manufactured to automatically inject and transfer samples. We perform a safe foundation and seismic design when install the equipment. There are many other components for various polymerizations such as mixture reactor and pump. This composition facilitates a phased polymerization and handles a certain amount at one time.

PMR 1000 is made from stainless steel or carbon steel, and the inside is made from double junction nickel. The cover of vessel is fixed, and samples are putted through pipes. Nozzle basically consists of injection line, emission line, safe vent and thermocouple. Magnetic bar and there are multiple options such as deep tube for gas injection during the process, and cooling coil for rapid cooling. |

|

| |

|

| |

Dimension Dimension |

| Working Capacity |

1000ℓ (Inside size :

φ

745 ㎜ X 2,300 ㎜) |

| Working Temp. |

~ 130 ℃ |

| Working Pressure |

5 ㎏/㎠ |

| Process Type |

Continuous Type |

| Material |

SUS316 |

| Main Seal |

PTFE(sheets gasket seal) |

| Closure Type |

Bolt Closure |

| Agitator |

Magnedrive |

| MD Rotational Control |

Inverter Control |

| Impeller |

Propeller(2ea) x Anchor(1ea) |

* Main reactor

* Oil Tank - 1set

* Mixing Vessel - 1set

* Impeller & Shaft

|

|

| |

Features of PMR 1000 Features of PMR 1000 |

| Safety |

• Design and manufacture according to ASME U1, U2 pressure vessel standard

• Safety and accuracy by double control system for pressure.

• Assure safety and accuracy by double pressure control system.

• Continuous equipment management by alarm list record. |

| Convenience |

• Compact workspace is compatible with various environmental conditions.

• Control system controls all operations after putting material

• Convenient cleaning by easy assembly / disassembly |

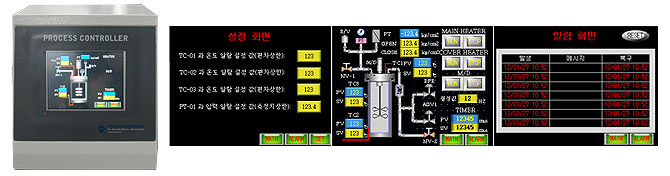

| Control System |

• Convenient touch screen

• Accurate testing by automatic system |

|

|

| |

Specification Specification |

| * PMR 1500 Series |

| Series |

Liner Type |

Temperature |

Pressure |

Max.

Tank

Volume |

Material |

| PMR1000-1501 |

1000ℓ |

150 ℃ |

8

㎏/㎠ |

1500ℓ |

SUS 316 (+ Ni) |

| PMR1000-1502 |

1000ℓ x 2 |

150 ℃ |

8 ㎏/㎠ |

2000ℓ |

SUS 316 (+ Ni) |

|

| |

| * PMR 2000 Series |

| Series |

Liner Type |

Temperature |

Pressure |

Max.

Tank

Volume |

Material |

| PMR2000-1501 |

2000ℓ |

150 ℃ |

8

㎏/㎠ |

2500ℓ |

SUS 316 (+ Ni) |

| PMR2000-1502 |

2000ℓ x 2 |

150 ℃ |

8 ㎏/㎠ |

4000ℓ |

SUS 316 (+ Ni) |

|

| |

| * PMR 3000 Series |

| Series |

Liner Type |

Temperature |

Pressure |

Max.

Tank

Volume |

Material |

| PMR3000-1501 |

3000ℓ |

150 ℃ |

8

㎏/㎠ |

4000ℓ |

SUS 316 (+ Ni) |

| PMR3000-1502 |

3000ℓ x 2 |

150 ℃ |

8 ㎏/㎠ |

5000ℓ |

SUS 316 (+ Ni) |

|

| |

| * PMR 5000 Series |

| Series |

Liner Type |

Temperature |

Pressure |

Max.

Tank

Volume |

Material |

| PMR5000-1501 |

5000ℓ |

150 ℃ |

8 ㎏/㎠ |

6000ℓ |

SUS 316 (+ Ni) |

| PMR5000-1502 |

5000ℓ x 2 |

150 ℃ |

8 ㎏/㎠ |

7000ℓ |

SUS 316 (+ Ni) |

|

* Double junction nickel can be used for corrosion resistance.

*Impeller and Thermowell can apply Teflon / Meta Coating. |

| Please contact our sales team to inquire about other specification |

| |

Technical sales team : +82-42-931-6100 (Ext. 1) |

|

|